PROCESS EQUIPMENT

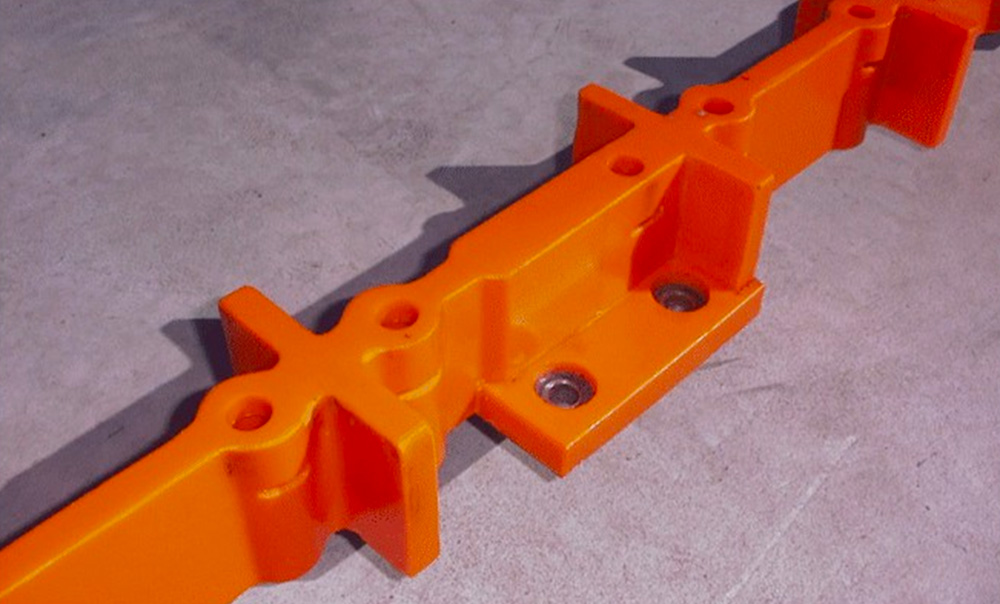

CONTACT USConcord apply polyurethane protective coating systems to agitator – mixer blades and shafts. The Concord system has proven its durability through outstanding hydrolytic stability, chemical and abrasion resistance when in service. Our polyurethane coating is a hot cast process and provides full encapsulation of steel work. Mixer blades and shafts are cast in one integral component, free of seams and joins.

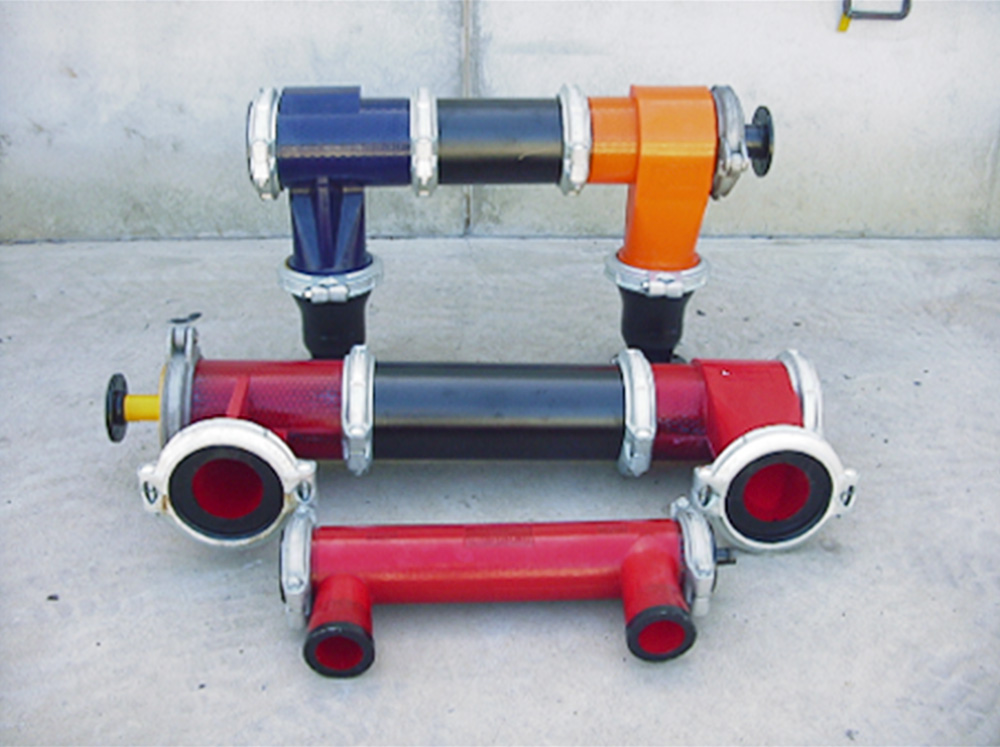

Cyclones

Concord manufactures and supplies Cyclones for use in mineral processing. Concord Cyclones range in size from 45mm to 1200mm. Materials of construction includes polyurethane, ceramic, rubber and steel lined cyclones.

Concord are capable of manufacturing complete cyclone clusters to include cyclones, pressure distributors, underflow / overflow launders, valves and piping.

Concord manufactures and stock cyclone replacement parts – spigots, vortex finders, feed chambers, cones, parts in polyurethane and ceramic. We are also able to manufacture and supply standard and non-standard cyclone components to client requirements.

Densifiers

The Concord Densifier can be used in a variety of roles: Densifiers are used to remove water and purge slimes from a feed pulp of ferrosilicon or magnetite heavy media thereby producing a dense underflow and a dilute overflow. Concord Densifier are used to maintain and control circulating media density. Densifiers are also used to effectively recover media in dilute circuits. Densifiers may be used on dilute circuits to concentrate media prior to magnetic separation, in this role the densifier performs an effective de-sliming and de-watering function.

Densifiers differ from Cyclones in three distinct ways. Firstly they work over a broad range of operating pressures from 300 – 700 KPa. Secondly Densifiers handle much greater volumetric feed and finally Densifiers are used primarily to perform water – solids separation.

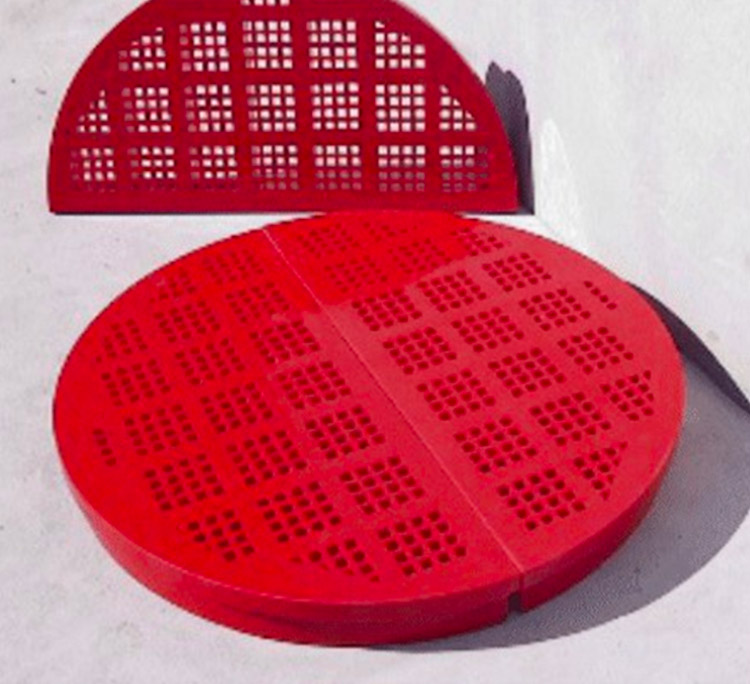

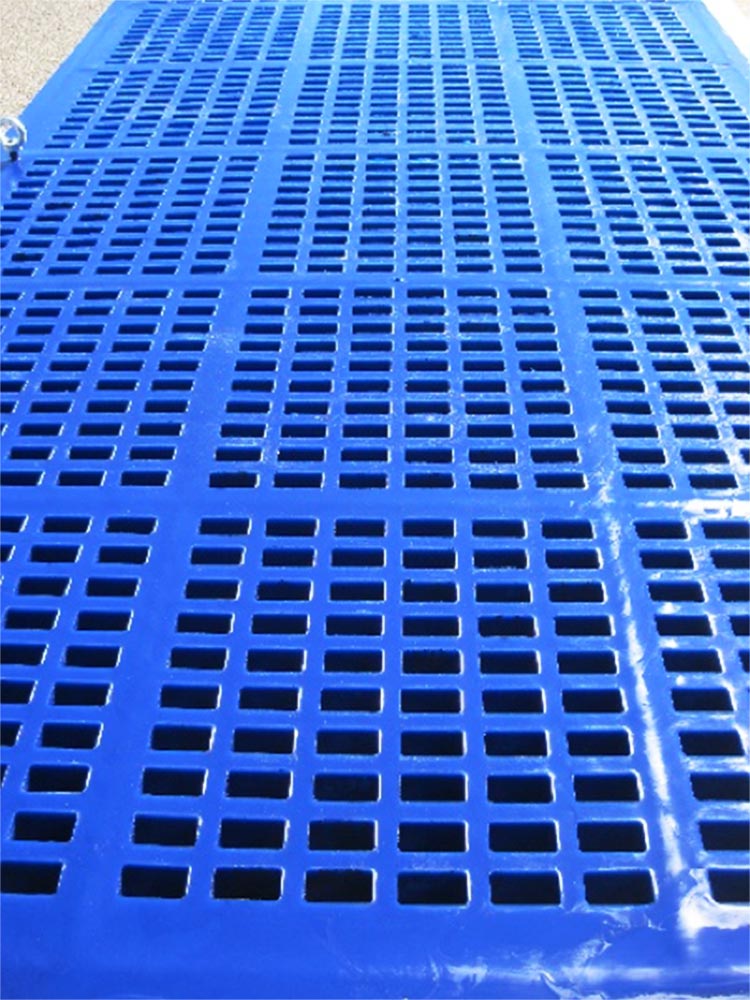

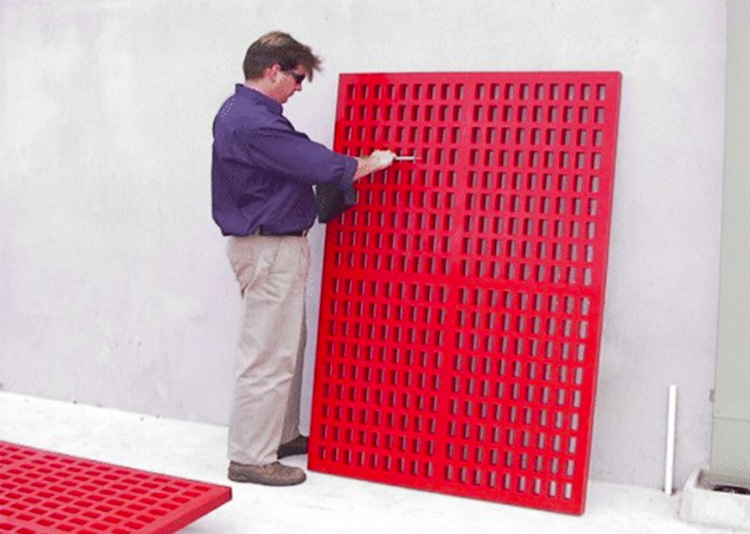

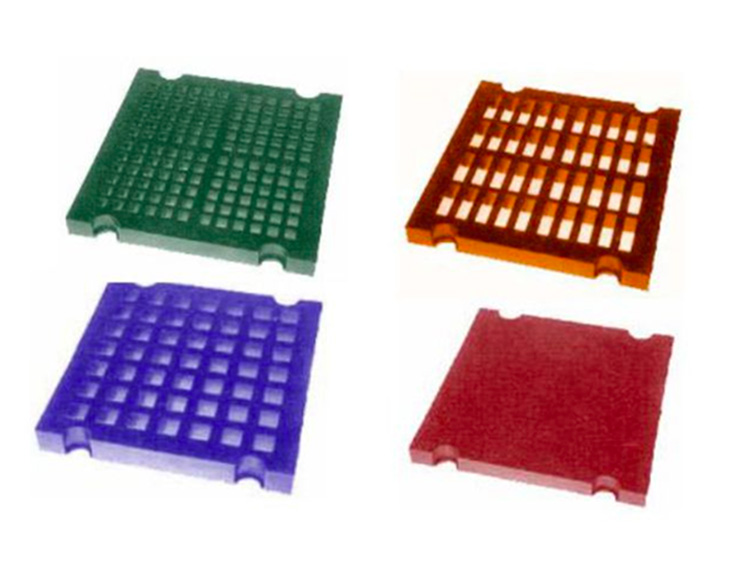

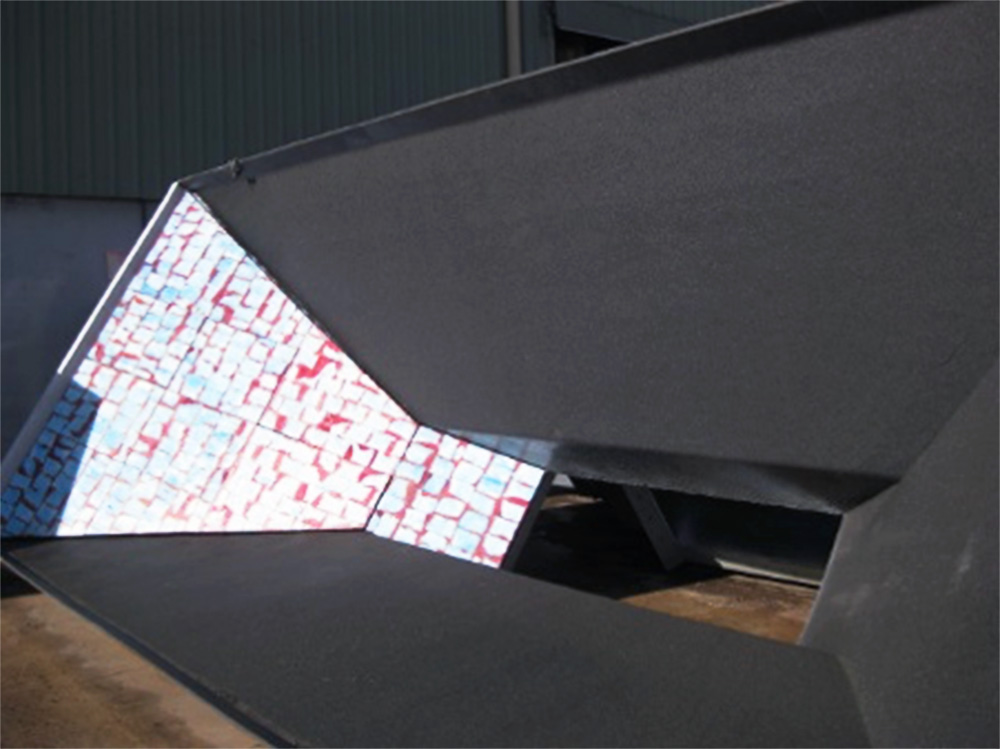

Screen Protection

Concord manufacture and supply polyurethane screen protection liners, screen rails, screen side bars and panels. Aperture panels are available in standard sizes and can be custom made to client requirement in terms of size or polyurethane formulation.

All Concord screen and trommel parts are moulded in premium grade elastomer. Steel reinforcing is incorporated into moulded components to ensure maximum strength.

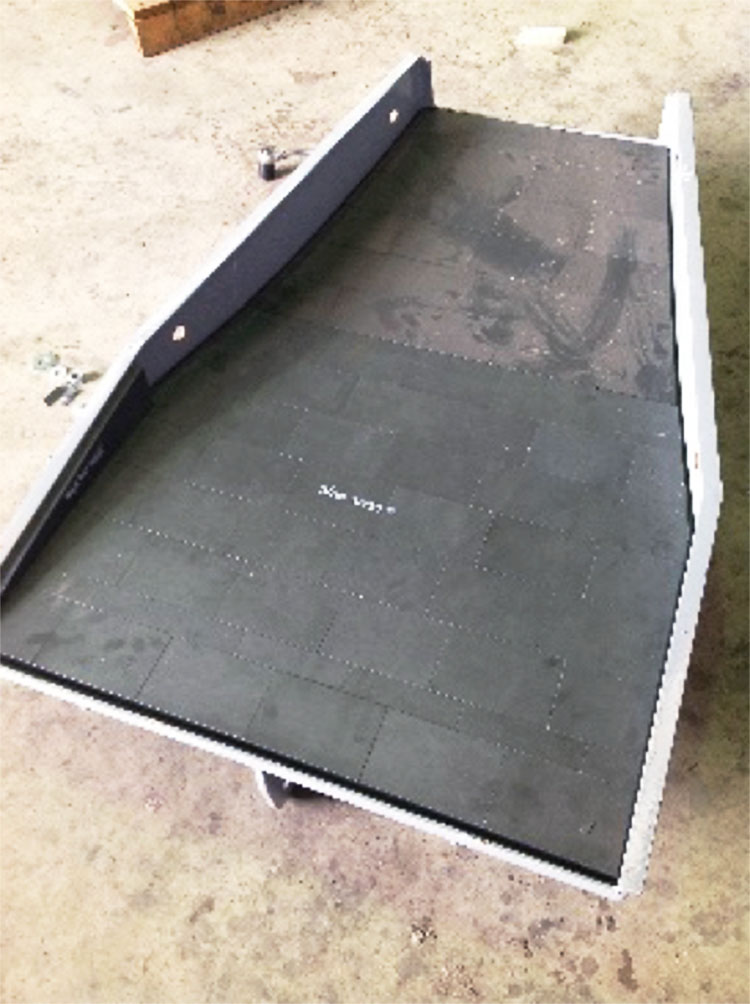

Wear Liners

Concord Wear Liners help clients reduce abrasion throughout their operation. This is achieved by working with our customers to choose the cost effective wear material. Concord Wear Liners always deliver the best possible performance in the most demanding situations.

Concord Wear Liner Material

- Metal

- Polyurethane

- Ceramic

- Composite

Concord offer in-house design, manufacture and installation of standard and non-standard wear liners and wear lining systems.